and everything we stand for

and everything we stand for

We would like to introduce ourselves to you and your company.

Tri-Tech has been in business for 20 years and has grown to employ over 30 people. We have a reputation for quality work at a reasonable price, along with great service. Tri-Tech is an experienced, honest and hardworking company that emphasizes service and customer satisfaction.

Tri-Tech’s ability in design, manufacturing, repairs, incorporating engineer changes, and gauge certification are the “World Class” results that are expected and demanded of suppliers for their customers in the automotive and non-automotive industries utilizing Dimensional Metrology.

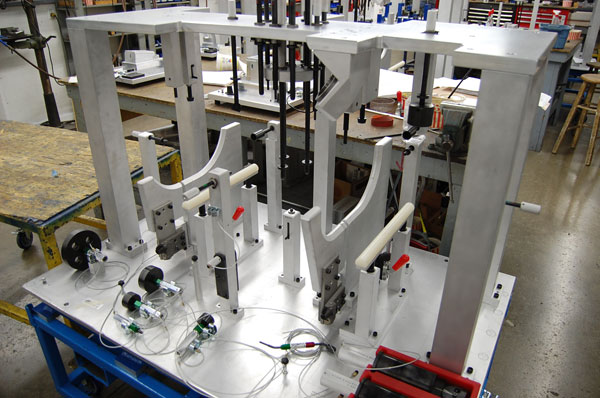

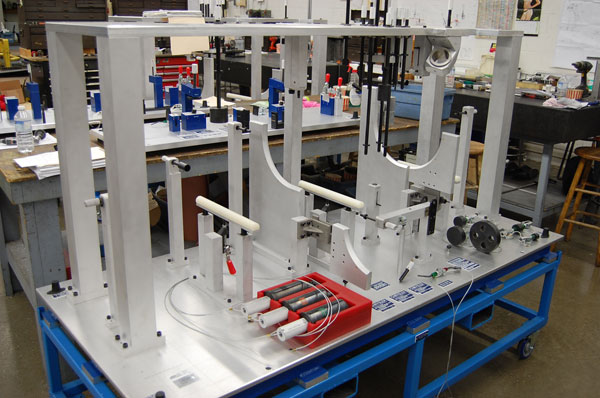

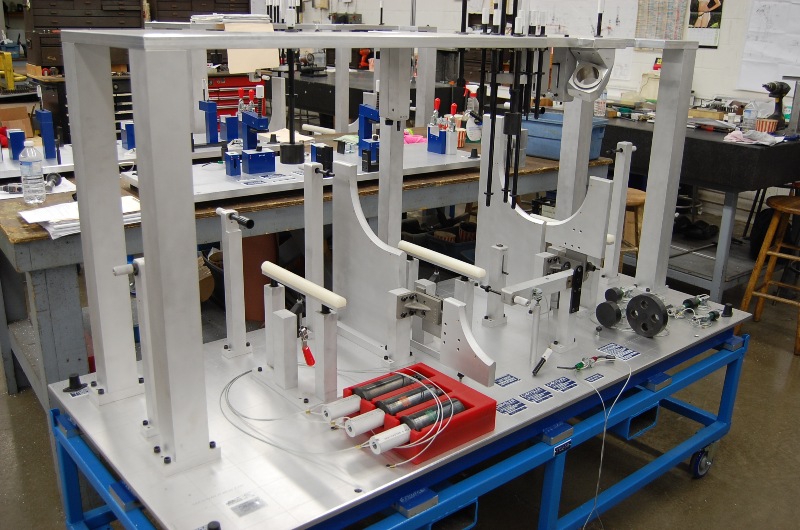

Our capabilities encompass a variety of fixtures such as: Attribute, Variable, SPC (with data collection devices and without), LMI Fixtures, CMM Holding Fixtures & Weld/Assembly Fixtures.

Tri-Tech Models and Fixtures is proud to supply automotive Tier 1 and 2 customers, since the company’s inception. We have also exceeded their requirements by obtaining the ISO – 9001 Quality Systems Registration and we have successfully achieved the status of an “Approved Source” for the Chrysler Corporation.

"A company I can count on for support, expertise, quality and On Time delivery"

From a customer's point of view Tri-Tech Fixtures is an excellent full service Gage and fixture shop. Quoting is prompt and competitive and delivery is always on time with certifications.

Sheffield endeavor 2m x 1.2m x 1m Measuring capacity, running pcdmas software

Part layouts, reverse engineering

Part certification

Fixture/ Gauge Certification / Re- certification

Gauge R & R

Capability Studies

CAD stations utilize Cimatron

IGES, DXF, Translators

Powermill Step, Parasolid

2D/3D Design

3D Surface Model

1 CNC – 20” x 40” x 28” Capacity

1 CNC – 30” x 70” x 28” Capacity

1 CNC – 30” x 60” x 30” Capacity

3 Surface Grinders

10 Milling Machines (with readouts)

2 Lathes

2 Cut-off Saws

3 Drill Presses

7 Granite Surface Plates

1 Radial Arm Drill

2 Welders / Arc / Stick Tig

From product design to product delivery, we are continually incorporating techniques that provide the efficiency and accuracy that are now required in the “High Tech” industry.

The pursuit of continuous improvement activities ensure Tri-Tech Fixtures of being on the “leading edge”. The standard of conduct and basic principle of Tri-Tech is to surpass our customers expectations.

The entire staff continually strives to achieve excellence in its daily activities through advanced training and personal development skills that have been predetermined by the management team and are evaluated against the benchmark of our industry.

Through employee involvement and the team concept encouraged from all the departments, Tri-Tech has developed policies and procedures to ensure employee satisfaction, at the same time to provide a product and service that is complimented and respected by our customers.

We take great pride in our quality, work ethic and our genuine desire to be the “Best-In-Class” fixture, gauge and inspection facility.

With 30 plus years of design and engineering experience utilizing the latest in CAD/CAM software, the Engineering Department provides clear, concise and accurate designs for customer approval and detail drawing and instructions for the manufacturing staff.

The design and engineering staff provides services to remain abreast of the new technologies being offered in the industry.

The quality department is comprised of over 60 years of automotive Tier 1, 2 & 3 experience along with non-automotive Dimensional Metrology training. We are proud to communicate our successful achievement of ISO 9001.

Acceptance to the Chrylser Approved Source list in our commodity.

The present development and implementation of the required systems to be in compliant with guide 25 and QS-9000 T&E Registration.

Through the philosophy of “Quality First” and “First in Quality” the manufacturing and build process has a proven record of providing the customer accurate, repeatable and durable product.

All employees have been encouraged to strive for perfection and the “Zero Defects” attitude to promote and adhere to. This attitude and perseverance has lead Tri-Tech Fixtures to be known as a “World Class” fixture and gauge designer and manufacturer.

5355 Outer Drive, Windsor, ON N9A 6J3

(Phone) 519-737-9075

(Fax) 519-737-9977

Dwaine Sutts, Sales/ Program Manager

D.Sutts@tritechfixtures.com

Ken Camphorst, Plant Manager

K.Camphorst@tritechfixtures.com

Scott Meyrick, Engineering

S.Meyrick@tritechfixtures.com

Terry Tomicic, President

T.Tomicic@tritechfixtures.com

We would like to introduce ourselves to you and your company.

Tri-Tech has been in business for 20 years and has grown to employ over 30 people. We have a reputation for quality work at a reasonable price, along with great service. Tri-Tech is an experienced, honest and hardworking company that emphasizes service and customer satisfaction.

Tri-Tech’s ability in design, manufacturing, repairs, incorporating engineer changes, and gauge certification are the “World Class” results that are expected and demanded of suppliers for their customers in the automotive and non-automotive industries utilizing Dimensional Metrology.

Our capabilities encompass a variety of fixtures such as: Attribute, Variable, SPC (with data collection devices and without), LMI Fixtures, CMM Holding Fixtures & Weld/Assembly Fixtures.

Tri-Tech Models and Fixtures is proud to supply automotive Tier 1 and 2 customers, since the company’s inception. We have also exceeded their requirements by obtaining the ISO – 9001 Quality Systems Registration and we have successfully achieved the status of an “Approved Source” for the Chrysler Corporation.

"A company I can count on for support, expertise, quality and On Time delivery"

- Tom Clark

From a customer's point of view Tri-Tech Fixtures is an excellent full service Gage and fixture shop. Quoting is prompt and competitive and delivery is always on time with certifications.

- Ludwig Dobmeier

Sheffield endeavor 2m x 1.2m x 1m Measuring capacity, running pcdmas software

Part layouts, reverse engineering

Part certification

Fixture/ Gauge Certification / Re- certification

Gauge R & R

Capability Studies

CAD stations utilize Cimatron

IGES, DXF, Translators

Powermill Step, Parasolid

2D/3D Design

3D Surface Model

E-mail capabilities for CAD and other files: s.meyrick@tritechfixtures.com

1 CNC – 20” x 40” x 28” Capacity

1 CNC – 30” x 70” x 28” Capacity

1 CNC – 30” x 60” x 30” Capacity

3 Surface Grinders

10 Milling Machines (with readouts)

2 Lathes

2 Cut-off Saws

3 Drill Presses

7 Granite Surface Plates

1 Radial Arm Drill

2 Welders / Arc / Stick Tig

From product design to product delivery, we are continually incorporating techniques that provide the efficiency and accuracy that are now required in the “High Tech” industry.

The pursuit of continuous improvement activities ensure Tri-Tech Fixtures of being on the “leading edge”. The standard of conduct and basic principle of Tri-Tech is to surpass our customers expectations.

The entire staff continually strives to achieve excellence in its daily activities through advanced training and personal development skills that have been predetermined by the management team and are evaluated against benchmark of our industry.

Through employee involvement and the team concept encouraged from all the departments, Tri-Tech has developed policies and procedures to ensure employee satisfaction, at the same time to provide a product and service that is complimented and respected by our customers.

We take great pride in our quality, work ethic and our genuine desire to be the “Best-In-Class” fixture, gauge and inspection facility.

With 30 plus years of design and engineering experience utilizing the latest in CAD/CAM software, the Engineering Department provides clear, concise and accurate designs for customer approval and detail drawing and instructions for the manufacturing staff.

The design and engineering staff provides services to remain abreast of the new technologies being offered in the industry.

The quality department is comprised of over 60 years of automotive Tier 1, 2 & 3 experience along with non-automotive Dimensional Metrology training. We are proud to communicate our successful achievement of ISO 9001.

Acceptance to the Chrylser Approved Source list in our commodity.

The present development and implementation of the required systems to be in compliant with guide 25 and QS-9000 T&E Registration.

Through the philosophy of “Quality First” and “First in Quality” the manufacturing and build process has a proven record of providing the customer accurate, repeatable and durable product.

All employees have been encouraged to strive for perfection and the “Zero Defects” attitude to promote and adhere to. This attitude and perseverance has lead Tri-Tech Fixtures to be known as a “World Class” fixture and gauge designer and manufacturer.

5355 Outer Drive, Windsor, ON N9A 6J3

(Phone) 519-737-9075

(Fax) 519-737-9977

Dwaine Sutts, Sales/ Program Manager

D.Sutts@tritechfixtures.com

Ken Camphorst, Plant Manager

K.Camphorst@tritechfixtures.com

Scott Meyrick, Engineering

S.Meyrick@tritechfixtures.com

Terry Tomicic, President

T.Tomicic@tritechfixtures.com

We would like to introduce ourselves to you and your company.

Tri-Tech has been in business for 20 years and has grown to employ over 30 people. We have a reputation for quality work at a reasonable price, along with great service. Tri-Tech is an experienced, honest and hardworking company that emphasizes service and customer satisfaction.

Tri-Tech’s ability in design, manufacturing, repairs, incorporating engineer changes, and gauge certification are the “World Class” results that are expected and demanded of suppliers for their customers in the automotive and non-automotive industries utilizing Dimensional Metrology.

Our capabilities encompass a variety of fixtures such as: Attribute, Variable, SPC (with data collection devices and without), LMI Fixtures, CMM Holding Fixtures & Weld/Assembly Fixtures.

Tri-Tech Models and Fixtures is proud to supply automotive Tier 1 and 2 customers, since the company’s inception. We have also exceeded their requirements by obtaining the ISO – 9001 Quality Systems Registration and we have successfully achieved the status of an “Approved Source” for the Chrysler Corporation.

"A company I can count on for support, expertise, quality and On Time delivery"

- Tom Clark

From a customer's point of view Tri-Tech Fixtures is an excellent full service Gage and fixture shop. Quoting is prompt and competitive and delivery is always on time with certifications.

- Ludwig Dobmeier

Sheffield endeavor 2m x 1.2m x 1m Measuring capacity, running pcdmas software

Part layouts, reverse engineering

Part certification

Fixture/ Gauge Certification / Re- certification

Gauge R & R

Capability Studies

CAD stations utilize Cimatron

IGES, DXF, Translators

Powermill Step, Parasolid

2D/3D Design

3D Surface Model

E-mail capabilities for CAD and other files: s.meyrick@tritechfixtures.com

1 CNC – 20” x 40” x 28” Capacity

1 CNC – 30” x 70” x 28” Capacity

1 CNC – 30” x 60” x 30” Capacity

3 Surface Grinders

10 Milling Machines (with readouts)

2 Lathes

2 Cut-off Saws

3 Drill Presses

7 Granite Surface Plates

1 Radial Arm Drill

2 Welders / Arc / Stick Tig

From product design to product delivery, we are continually incorporating techniques that provide the efficiency and accuracy that are now required in the “High Tech” industry.

The pursuit of continuous improvement activities ensure Tri-Tech Fixtures of being on the “leading edge”. The standard of conduct and basic principle of Tri-Tech is to surpass our customers expectations.

The entire staff continually strives to achieve excellence in its daily activities through advanced training and personal development skills that have been predetermined by the management team and are evaluated against benchmark of our industry.

Through employee involvement and the team concept encouraged from all the departments, Tri-Tech has developed policies and procedures to ensure employee satisfaction, at the same time to provide a product and service that is complimented and respected by our customers.

We take great pride in our quality, work ethic and our genuine desire to be the “Best-In-Class” fixture, gauge and inspection facility.

With 30 plus years of design and engineering experience utilizing the latest in CAD/CAM software, the Engineering Department provides clear, concise and accurate designs for customer approval and detail drawing and instructions for the manufacturing staff.

The design and engineering staff provides services to remain abreast of the new technologies being offered in the industry.

The quality department is comprised of over 60 years of automotive Tier 1, 2 & 3 experience along with non-automotive Dimensional Metrology training. We are proud to communicate our successful achievement of ISO 9001.

Acceptance to the Chrylser Approved Source list in our commodity.

The present development and implementation of the required systems to be in compliant with guide 25 and QS-9000 T&E Registration.

Through the philosophy of “Quality First” and “First in Quality” the manufacturing and build process has a proven record of providing the customer accurate, repeatable and durable product.

All employees have been encouraged to strive for perfection and the “Zero Defects” attitude to promote and adhere to. This attitude and perseverance has lead Tri-Tech Fixtures to be known as a “World Class” fixture and gauge designer and manufacturer.

5355 Outer Drive, Windsor, ON N9A 6J3

(Phone) 519-737-9075

(Fax) 519-737-9977

Dwaine Sutts, Sales/ Program Manager

D.Sutts@tritechfixtures.com

Ken Camphorst, Plant Manager

K.Camphorst@tritechfixtures.com

Scott Meyrick, Engineering

S.Meyrick@tritechfixtures.com

Terry Tomicic, President

T.Tomicic@tritechfixtures.com